Our History

Scarrott Metallurgical Company

Scarrott Metallurgical Company, known also as International Metallurgical Services, was founded in 1977 by David Scarrott and business partner Robert Fairbanks. In a time of new space exploration vessels and the introduction of advanced and rare materials, SMC was founded as a place to have the questions raised by innovation tested and answered. The road leading to the founding of SMC is long and deep in history, beginning with David Scarrott himself. The fact is that by the time David Scarrott had created SMC, David had already accumulated 25 years of personal experience in the heat treating industry.

At the age of 16, as part of his university program, David landed a five-year apprenticeship with a jet engine manufacturer. “I didn’t know what it was,” says Dave, “but they said it was up and coming so I thought “Ok, Let’s see.” Earning a measly 2 ½ £ a week, he was put to work in the forge, casting, plating, and heat treatment shops. Mostly, he found himself in the lab experimenting with different metals and techniques. Curiosity was a tool David used for exploring new ideas and that continues to be core to SMC’s mission.

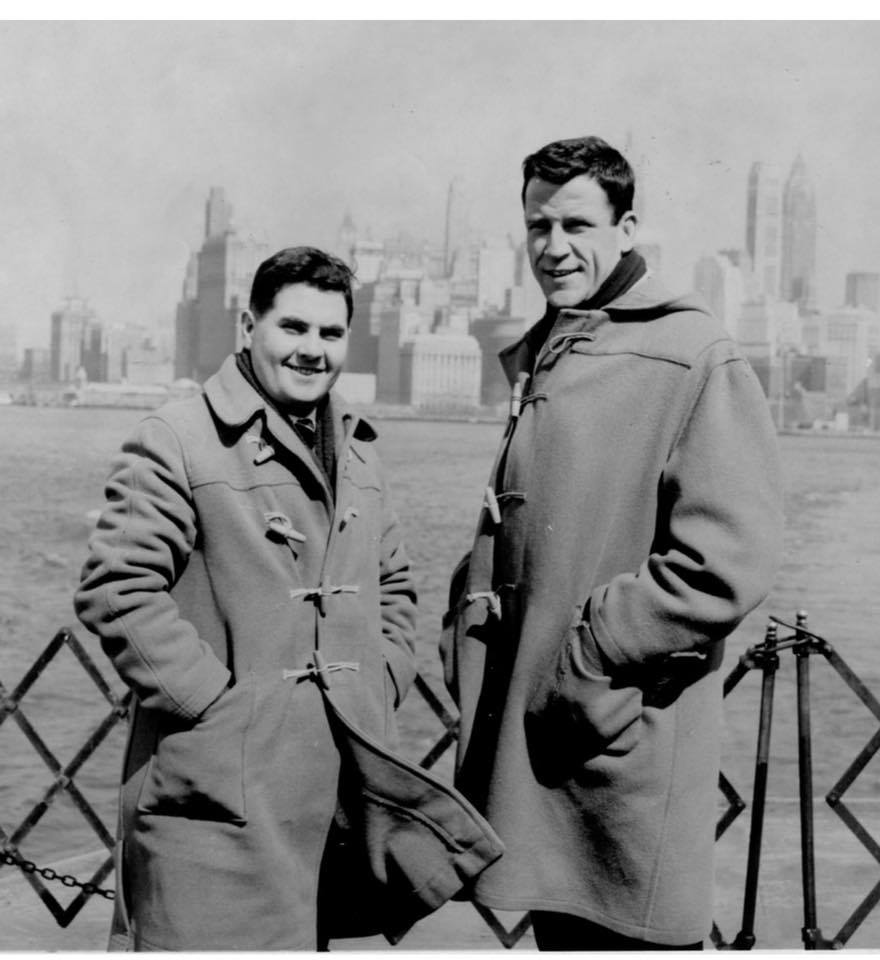

Eight years later, around 1960, he came to the United States with his good friend Ralph Jones who would later also become a part of Scarrott Metallurgical. Initially, they both came looking for whatever work they could find. After a one-sentence interview (“I know about furnaces”), David was given a job as a garbage man three floors below ground at a May Co. department store in the San Fernando Valley. His responsibilities were simple: watch the trash coming down the shoot and keep the smoke alarm from going off. Things were destined to be different for David, though. On the third day, a newspaper came down the chute, opened to an ad for a metallurgy position, and that was that. David walked off the job, without picking up his check, smoke alarm blaring.

After two years with the metallurgy company he found in the newspaper, Rockwell Rocketdyne, a newer aerospace company, invited him to join their team based on his accumulated metallurgy experience. Responding to President Kennedy’s goal to place a man on the moon that decade, Rocketdyne employees were designing and building rocket engines to power most of the space race spacecrafts. With the advanced nature of materials and processes being required for the space race which no one was deeply familiar, David was put in technical charge of heat treating.

He was confident in the work he had done but, still, he felt some relief when he watched the Lunar Module, carrying astronauts Neil Armstrong and Buzz Aldrin, gracefully lift off the moon on its way to dock with the Command/Service Module. Being the first attempt at such a thing, “you never can tell,” said David. It was thrilling knowing that his part in bringing the astronauts safely home had been successful.

After his success with Rocketdyne, word of his knowledge began to spread throughout the industry and his services were more and more in demand. He was being asked for consultation work and as a speaker at many events both locally and internationally. David worked through a string of various heat treating and brazing companies when it occurred to him that their methods were not satisfactory. At the time, most companies had acknowledged that errors would occur when treating parts and felt that manufacturing extra parts to make up for those errors would be sufficient for the losses. It was at this last position with Techni-Braze that David’s philosophy and mission came into full view. David could not tolerate that standard of quality within the industry and believed he could change that.

With the success of the moon landing, the space program would soldier on with the development of the brand new Space Shuttle Program. The Space Shuttle Program was just getting started, and engineers were using exotic metals that needed to be heat treated in a super clean environment and brazing techniques that had yet to be created. David knew that his deep experience and superior commitment to quality would well serve this market. Combined with Bob Fairbanks brilliance, depth of knowledge, and his commitment to quality, the two of them set out to make Scarrott Metallurgical the premier location for heat treating, and more importantly, as a source of problem solving for their clients. They succeeded in both aspects and the company carries on that tradition today.

Quality has always been David’s number one priority. Early in his apprenticeship, Dave was made aware that errors could easily cost people’s lives. But his commitment to quality may have been seeded much earlier in life. Quality, incidentally, was instilled in David at a very young age. Growing up during World War II in the poorest part of his hometown of Cheltenham, David’s family had little. Still, the Scarrott house was always the nicest on the block because David’s father was obsessed with quality.

Seurenda Liberty Scarrott, David’s father, bought fruits and vegetables from local farmers to sell to the shopkeepers in town. Before purchasing, he’d stick his hand in every box or bag, squeezing the potatoes and squash to make sure they weren’t going soft. Storekeepers told young Dave they bought from his father because he always provided the best quality. David knew this was true. He remembered driving once with his father to a nearby town to sell produce. It was a slow, 16-mile trek on a country road in a van without refrigeration. But David’s father would not be thwarted. Instead of arriving with understandably wilted vegetables, he stopped at a wild spring and dunked the apples and watercress to ensure their freshness. Competing with the “big boys” and their fleet of trucks, Dave’s dad secured the business of small shopkeepers because of consistent quality.

In his own business, the ever-present drive to consistently deliver superior quality led Dave and his employees to develop new systems, such as residual gas analysis, to ensure jobs are done precisely and without contamination. Like his father stopping at a spring to spruce vegetables, “We continuously invest money, time, and ingenuity into our operation so we can deliver the best,” says Scarrott. No one knows better than Dave that limited production with costly materials and state of the art manufacturing techniques gives heat treaters very expensive parts to process. There is nothing David hates more than to tell a customer he screwed up. “If we can’t do it right, we don’t do it at all.”

But quality is more than an issue of pride or even good business for Dave. “Quality keeps planes in the air and astronauts breathing,” he says. “We never forget that lives are more important than time or money.” All this emphasis on quality shows up time and again in SMC’s work product.

David has served as the President of the Metal Heat Treatment Association in Southern California; Chairman of the American Society of Metals, San Fernando Valley and Los Angeles chapters; and Chairman of the Westec convention. He is a frequent consultant, and International lecturer and speaker.

“It brings tears to my eyes when we see our products doing their jobs,” says Dave, “keeping people safe, taking part in history… It’s amazing.”

Such personal investment has propelled Scarrott Metallurgical Company to the top of its field.

In 2019, David’s daughter, Shannon, took over the reigns of the business and continued the family legacy all the way to March of 2024 when the company was sold to Thermal Tube Innovations.

“When you can’t afford a mistake, and can’t afford to make it again, Scarrott Metallurgical is the solution for you.”