High Vacuum Heat Treating

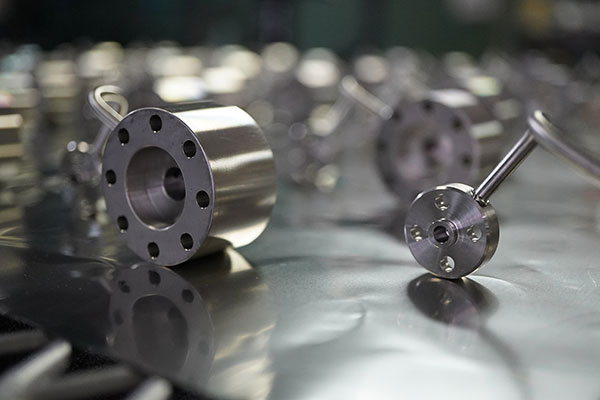

High Vacuum Heat Treating is the application of heat or cold to alter the metallurgical properties of a metal part in a vacuum atmosphere. Heat treatment processes are dependent on the clients needs but generally are applied to harden, soften, or relieve stress on a metal without changing the current shape. Metal heat treatment is often used to increase the overall strength of parts. It can also be used to ease machining, improve formability, or restore ductility after a cold forming operation, block and fluid cell forming, or deep draw stamping.

High Vacuum Heat Treating has several benefits to our clients. The elimination of oxidation and contamination on parts by using a vacuum atmosphere saves our clients cost and time associated with post processing such as cleaning. Within a vacuum, one advantage is the ability to more closely control and monitor heat ramp up and cooling rates for greater success in achieving our client goals, whatever they might be. As a side effect, because high vacuum heat treating does not produce any harmful or toxic waste gases, it is more environmentally friendly.

Nearly all forms of heat treating is available from Scarrott Metallurgical including annealing, stress relieving, precipitation heat treating, tempering, normalizing, and many more upon request. Some of the materials we routinely work with are stainless steels (300 series), precipitation hardened stainless steels, titanium, nickel based (Inconel 625 & 718), refractory metals (Nb & Mo) and other exotic alloys. Our team is here to evaluate your needs and help guide your team on the correct process and alloy to save you time and cost expenditures.