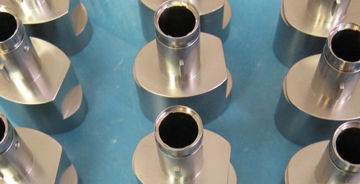

Vacuum Brazing and Heat Treating Services

Standard vacuum levels run at SMC are in the 10-5 torr range and high purity Ar with dew points of less than -110ºF significantly exceed industry standards. We pride ourselves on the cleanliness of our parts, the expertise of our brazing technicians and turn-around times. We run 7 days a week with 5 vacuum furnaces, a lower temperature air tempering furnace and liquid Nitrogen cold box. Additionally we do in-house hardness testing (both macro and micro) along with Helium Leak Testing down to 10-8 torr to verify our heat treatment and brazing processes.